Hard Chrome Plating

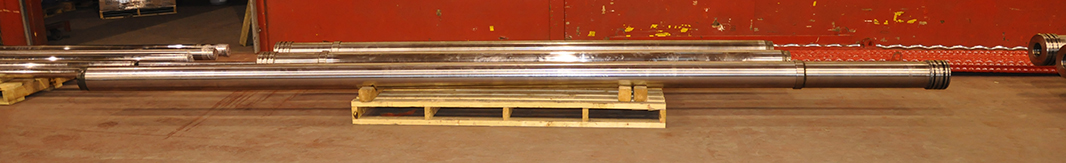

Moore’s Industrial Service Ltd. has the highest hard chrome plating capacity in North America and has one shop dedicated to servicing progressive cavity pump rotors and surface rotors. Our quality standards are the highest in the industry with tolerances up to +/- 0.002″ on rotors of up to 57 feet. Only the hardest chrome (Heef 25) is used. We also provide chrome stripping, welding and repair services. Moore’s specializes in PCP rotors, PDM rotors, surface pump rotors, industrial rotors and sanitary rotors.

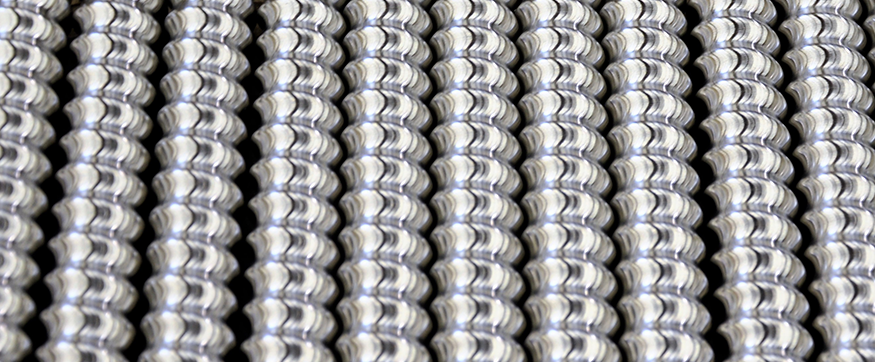

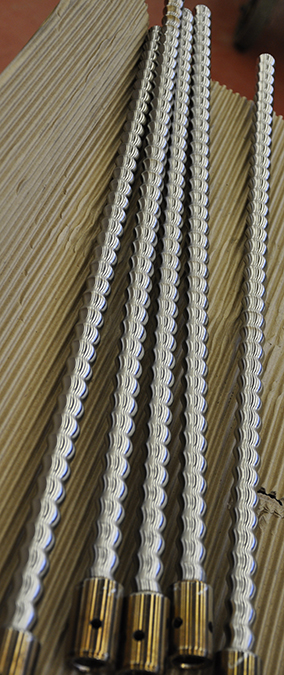

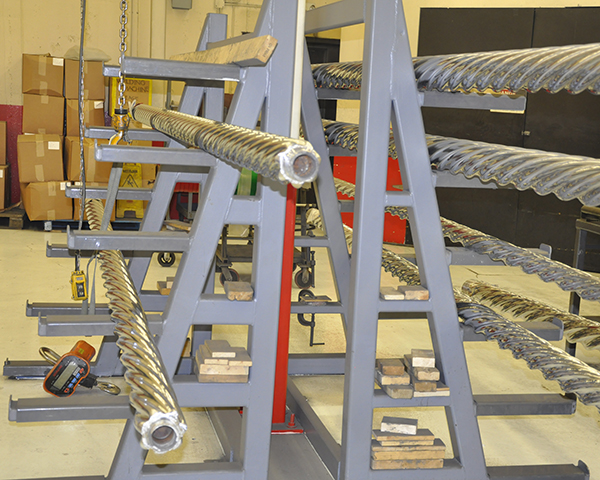

Chrome PCP Rotors

- We have a wide range of plating tanks ranging in depth from 8’ to 32’.

- Rotors are individually wrapped with a protective sock prior to shipping.

- We have three company owned semi-trailers that provide a free pickup and delivery service throughout Alberta and Western Saskatchewan.

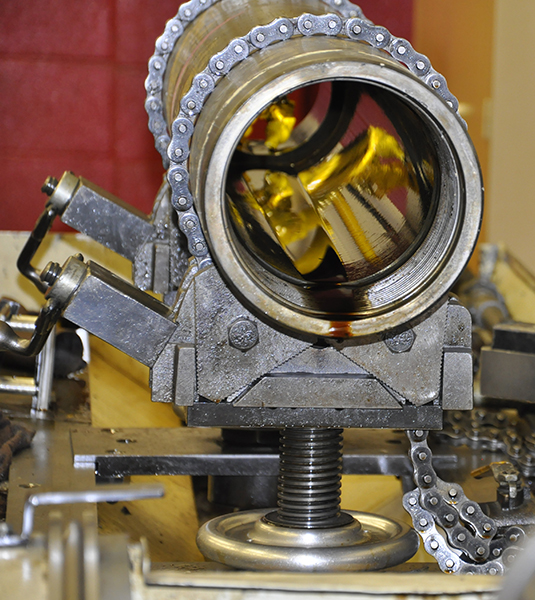

Chrome PDM Rotors

- Moore’s can provide rotor trays to make pick-up and return of rotors easier for our customers.

- Polishing is done on our custom-designed proprietary equipment.

- All power sections undergo precise finishing and rigorous testing before release for shipment.

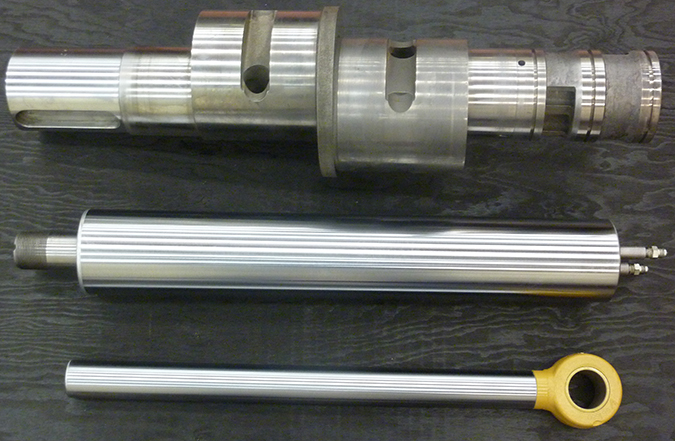

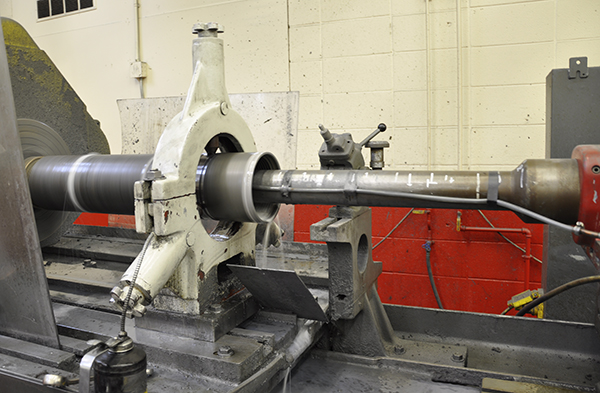

Chrome Rounds

- Internal chroming: hydraulic cylinders, bearing housings – up to 11” diameter, 5’ length.

- External hard chroming: large rounds up to 30” diameter, 16’ length and hydraulic rods and small rounds up to 57’ in length.

- Sulphamate Nickel: used as an undercoat to chrome to seal the base metal and stop contaminants reaching the base metal and delaminating the substrate.